Electrical & Control Projects

Automation

Common Oil Pipeline Oil Zone ECI System: (Design, Supply, Install and Commission)

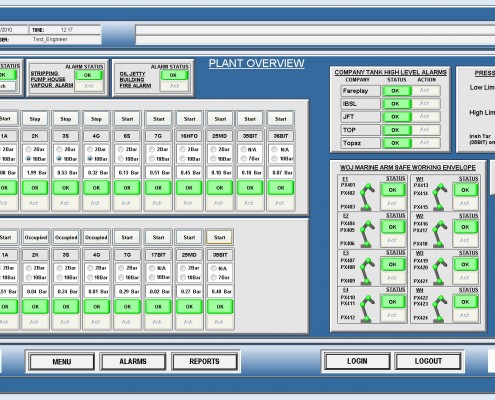

Project Objective: The primary objective of this project was to install a new Pipeline Pressure Monitoring and Alarms System for Dublin Port Oil Jetties in order to control the hazard of Electrostatic Discharge by controlling Pipeline Pressures. In addition to Pressure, other Alarms included Storage Tank High Level Alarms, Wind Speed Alarms and Marine Arm Limit Alarms. This project involved an extensive level of Validation in order to proof the Electrical / Electronic System to SIL (Safety Integrity Level) 2 in accordance with IEC 61508 and IEC 61511 standards.

CCTV

Project Objective: Install a CCTV System suitable for a hazardous area within a Class 1 Explosive Atmosphere in the Petro-Chemical Bulk Liquid and Oil Zone. This Camera System consisted of several state of the art Atex PTZ IP68 Robust Marine Rated Cameras suitable for extreme weather conditions.

Instrumentation

A total of 18 No. new Pressure Indicating Transmitters were installed on specified lines within the Ex Zone 1 Area. Stainless Steel Atex Pressure Transmitter range -1 – +20Barg. The new Pressure Indicating Transmitters provided a local and remote real time pressure reading for the specified lines. Pipeline Pressure values were interfaced with the controlled system in order to prevent over pressurising the pipelines.

Safety

Marine Arms Safety

Objective: To Increase the Safety of Marine Arm connections to Ships when offloading oil products. Marine Arm position and status tracked by Fail Safe SIL2 PNP Intrinsically Safe Inductive Proximity Sensors. These Safety Circuits, Sensors and PLC Hardware was validated in accordance with SIL and achieved the criteria for SIL2 accreditation.

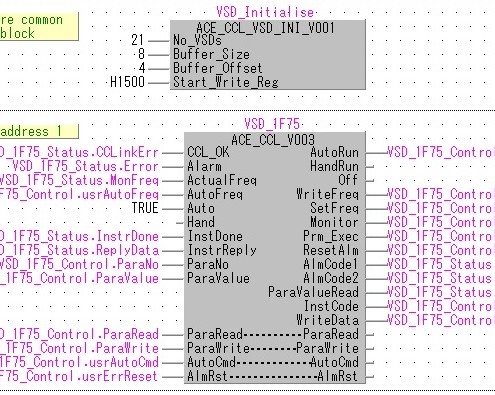

SCADA

Plant Maintenance Monitoring System

Project Objective: Develop a new SCADA Maintenance Page for Maintenance Personnel. This addition to the existing SCADA System was to facilitate placing plant (Marine Arms and Pipelines) IN and OUT of Action with Totalisers attached to count Working and Out of Action Hours. Functionality included forcing on and off the associated Alarms. The New Maintenance Page was implemented on the SCADA Server and 2 no. Atex MMI’s Remote SCADA Clients. Activity Report was also developed and implemented; the Report exported to Excel detailing time, date and actions, for all SCADA System interactions carried out.